Planning and Preparation: How To Pre Wire For Under Cabinet Lighting

Before diving into the wiring process, careful planning is crucial for a successful under-cabinet lighting installation. This involves understanding the different lighting options available, accurately measuring your space, selecting the right wiring, and ensuring compliance with local electrical codes.

Types of Under-Cabinet Lighting

The first step is to choose the type of under-cabinet lighting that best suits your needs and aesthetic preferences. Here are three popular options:

- LED Strips: These flexible strips offer a sleek and modern look, available in various colors and brightness levels. They are easy to install and can be customized to fit any shape or size.

- Puck Lights: These small, round lights provide focused illumination and are often used for accent lighting. They are typically available in warm white or cool white color temperatures.

- Recessed Lighting: These fixtures are installed directly into the cabinet, offering a clean and integrated look. They provide a more powerful and evenly distributed light compared to LED strips or puck lights.

Measuring the Space and Determining Wiring Length

Accurate measurements are essential for determining the required length of wiring. Use a measuring tape to measure the distance between the electrical outlet and the location of the under-cabinet lighting.

- Measure the distance from the outlet to the first light fixture: This will determine the length of the initial wire run.

- Measure the distance between each subsequent light fixture: This will help you calculate the total wire length needed.

- Add extra wire for flexibility: It’s always a good idea to add a few extra feet of wire to allow for adjustments during installation.

Selecting the Appropriate Wire Gauge and Type

The wire gauge and type depend on the power requirements of your under-cabinet lighting.

- Wire Gauge: The gauge refers to the thickness of the wire. A lower gauge number indicates a thicker wire, which can handle more current. For most under-cabinet lighting, 14-gauge wire is sufficient. However, if you are using high-power LED strips or multiple fixtures, 12-gauge wire may be necessary.

- Wire Type: The type of wire determines its insulation and protection. For under-cabinet lighting, use THHN or THWN wire, which are commonly used for residential wiring and are suitable for indoor use.

Identifying and Labeling Electrical Circuits

Before working with electrical wiring, it’s essential to identify the circuit that powers the kitchen outlet.

- Use a circuit tester: A circuit tester can help you identify the live wire, neutral wire, and ground wire in an outlet.

- Label the circuit: Once you have identified the circuit, label it clearly for future reference. This will help you avoid accidentally disconnecting the wrong circuit during installation.

Obtaining Permits and Inspections

In most jurisdictions, electrical work requires permits and inspections to ensure compliance with safety standards.

- Check local regulations: Contact your local building department to determine the specific requirements for electrical work in your area.

- Apply for a permit: Submit a permit application to the building department, providing detailed information about the project.

- Schedule an inspection: Once the wiring is complete, schedule an inspection by a qualified electrician to ensure it meets safety standards.

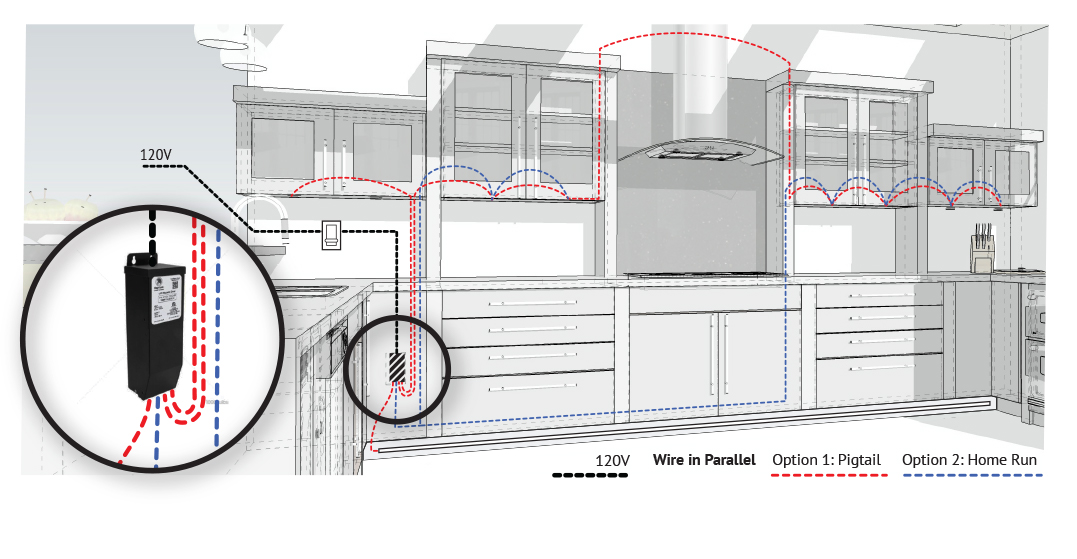

Running the Wiring

Running the wiring for under-cabinet lighting involves carefully planning and executing the installation process to ensure both functionality and safety. This section will delve into different methods for running the wiring, covering surface mounting, recessed installation, and using existing electrical boxes. Additionally, it will highlight crucial safety precautions to follow when working with electrical wiring.

Surface Mounting

Surface mounting is a straightforward method for running wiring under cabinets, making it ideal for DIY projects. This method involves attaching the wiring directly to the underside of the cabinets using staples, wire clips, or adhesive-backed wire channels.

- Staples: Staples are a cost-effective option for securing wiring, but they can damage the cabinet finish if not used carefully.

- Wire Clips: Wire clips offer a more secure and less damaging method of securing wiring compared to staples. They are available in various sizes and materials to accommodate different wire gauges.

- Adhesive-Backed Wire Channels: Adhesive-backed wire channels provide a neat and organized way to run wiring, concealing it from view. They are easy to install and come in various colors to match the cabinet finish.

Recessed Installation

Recessed installation involves hiding the wiring within the cabinet walls or ceiling, providing a cleaner and more integrated look. This method typically requires more effort and may involve cutting into existing structures.

- Running Wires Through Walls: Running wires through walls requires creating pathways using a drill and a hole saw. Ensure to use a stud finder to locate studs and avoid drilling into them.

- Running Wires Through Ceilings: Running wires through ceilings requires similar steps to running wires through walls, ensuring to avoid drilling into electrical or plumbing lines.

Using Existing Electrical Boxes

Utilizing existing electrical boxes is a convenient way to connect under-cabinet lighting. This method involves connecting the wiring to an existing junction box or outlet, minimizing the need for additional wiring.

- Connecting to a Junction Box: Connecting to a junction box allows for easy access to the wiring and provides a secure connection point.

- Connecting to an Outlet: Connecting to an outlet allows for easy installation and eliminates the need for a separate switch.

Securing Wiring to Structural Elements

Securing wiring to studs, joists, and other structural elements is crucial for ensuring a safe and stable installation.

- Staples: Staples are a common method for securing wiring to structural elements, but they should be used with caution to avoid damaging the wood.

- Wire Clips: Wire clips offer a more secure and less damaging method of securing wiring compared to staples. They are available in various sizes and materials to accommodate different wire gauges.

- Cable Ties: Cable ties are an excellent option for bundling wires and securing them to structural elements. They come in various sizes and strengths to accommodate different wiring needs.

Using Proper Wire Connectors and Termination Methods, How to pre wire for under cabinet lighting

Using proper wire connectors and termination methods is essential for ensuring a safe and reliable electrical connection.

- Wire Connectors: Wire connectors, also known as wire nuts, are used to connect two or more wires together. They come in various sizes to accommodate different wire gauges and should be properly installed to ensure a secure connection.

- Termination Methods: Termination methods involve connecting the wires to the electrical components, such as switches, outlets, and fixtures. These methods should be performed correctly to ensure a safe and reliable electrical connection.

Routing Wires Through Walls and Ceilings

Routing wires through walls and ceilings requires careful planning and execution to ensure a safe and efficient installation.

- Using a Stud Finder: Use a stud finder to locate studs and avoid drilling into them, which can damage the wall or ceiling structure.

- Using a Hole Saw: Use a hole saw to create pathways for the wires, ensuring to drill at an angle to avoid damaging the drywall or plaster.

- Using a Fish Tape: Use a fish tape to pull the wires through the pathways, ensuring to use a tape that is long enough to reach the destination.

Safety Precautions

Working with electrical wiring requires a high level of caution and safety awareness.

- Turn Off Power: Always turn off the power to the circuit before working with electrical wiring. Use a voltage tester to confirm that the power is off.

- Use Proper Tools: Use proper tools, such as wire strippers, crimpers, and voltage testers, to ensure a safe and reliable installation.

- Wear Protective Gear: Wear protective gear, such as safety glasses, gloves, and insulated footwear, to protect yourself from electrical shocks and injuries.

- Follow Electrical Codes: Always follow local electrical codes and regulations to ensure a safe and compliant installation.

Installing the Lighting Fixtures

Installing the lighting fixtures is the final step in the under-cabinet lighting project. This involves connecting the wires to the fixtures, grounding them properly, and ensuring they are functioning correctly. The type of fixture will influence the installation process.

Installing LED Strips

LED strips are a popular choice for under-cabinet lighting due to their flexibility and energy efficiency. Installing them involves attaching the strip to the underside of the cabinet and connecting it to the power source.

- Attaching the LED Strip: Use adhesive tape or clips to secure the LED strip to the underside of the cabinet. Ensure the strip is positioned evenly and securely.

- Connecting the Wires: Connect the wires from the LED strip to the power source. Typically, LED strips have two wires, one for positive (+) and one for negative (-). Match these wires to the corresponding wires on the power source.

- Grounding the LED Strip: LED strips often have a grounding wire that needs to be connected to a ground wire in the electrical box. This ensures that the fixture is properly grounded and safe to use.

Installing Puck Lights

Puck lights are small, circular lights that are often used for under-cabinet lighting. They are easy to install and can provide a bright, focused light.

- Mounting the Puck Lights: Puck lights are typically mounted with screws or adhesive tape. Choose a location that provides optimal lighting and avoids obstructing the cabinet doors.

- Connecting the Wires: Connect the wires from the puck light to the power source. Puck lights typically have two wires, one for positive (+) and one for negative (-). Match these wires to the corresponding wires on the power source.

- Grounding the Puck Lights: Puck lights often have a grounding wire that needs to be connected to a ground wire in the electrical box. This ensures that the fixture is properly grounded and safe to use.

Installing Recessed Lights

Recessed lights are installed flush with the underside of the cabinet and can provide a more integrated and sophisticated look.

- Cutting the Hole: Use a hole saw to cut a hole in the cabinet for the recessed light. The hole should be the same size as the light fixture.

- Connecting the Wires: Connect the wires from the recessed light to the power source. Recessed lights typically have two wires, one for positive (+) and one for negative (-). Match these wires to the corresponding wires on the power source.

- Grounding the Recessed Lights: Recessed lights often have a grounding wire that needs to be connected to a ground wire in the electrical box. This ensures that the fixture is properly grounded and safe to use.

- Securing the Fixture: Secure the recessed light fixture in the hole using screws or clips. Ensure the fixture is properly aligned and flush with the underside of the cabinet.

Connecting Multiple Fixtures

Connecting multiple fixtures to a single electrical circuit requires a junction box. This box allows you to connect the wires from each fixture to a single power source.

- Installing the Junction Box: Install the junction box in a convenient location near the power source. The box should be accessible for future maintenance.

- Connecting the Wires: Connect the wires from each fixture to the junction box. Use wire nuts to secure the connections.

- Grounding the Junction Box: Connect the grounding wires from each fixture to the grounding wire in the junction box. This ensures that all fixtures are properly grounded.

- Connecting to the Power Source: Connect the wires from the junction box to the power source. Use wire nuts to secure the connections. Make sure the power is off before connecting the wires.

Ensuring Even and Consistent Lighting

To ensure even and consistent lighting under cabinets, consider the following:

- Spacing the Fixtures: Space the fixtures evenly to avoid dark spots or overly bright areas.

- Using Dimmers: Use dimmers to adjust the brightness of the lights and create the desired ambiance.

- Choosing the Right Color Temperature: Select a color temperature that complements the overall lighting scheme in the kitchen.

Testing the Installed Lighting Fixtures

Once the fixtures are installed, test them to ensure they are functioning correctly.

- Turn on the Power: Turn on the power to the circuit and check that the lights are working.

- Check for Brightness: Ensure the lights are bright enough for the intended purpose.

- Check for Evenness: Make sure the lights are evenly distributed under the cabinets.

- Check for Grounding: Test the grounding of the fixtures to ensure they are safe to use.

How to pre wire for under cabinet lighting – Imagine your kitchen, bathed in warm, inviting light, illuminating every countertop detail. Before you even start building your dream kitchen, envision the glow of under cabinet lighting. Pre-wiring for this feature is a simple yet powerful step. For inspiration, check out the utilitech under cabinet lighting reviews , which highlight the transformative power of this lighting choice.

By planning ahead, you’ll not only enhance your kitchen’s functionality but also ensure a seamless installation for your under cabinet lighting, a choice that will illuminate your culinary adventures for years to come.

Imagine your kitchen transformed, bathed in a warm, inviting glow from perfectly placed under-cabinet lighting. This is a dream within reach, and it all starts with pre-wiring. Before you even consider the perfect countertop or backsplash, consider the electrical needs of your space.

If you’re looking for a new place to make this vision a reality, 1 bedroom and den apartments near me could be the perfect starting point. Once you’ve found your ideal space, the possibilities for creating a stunning, functional kitchen with pre-wired under-cabinet lighting are endless.